- Suits most architectural styles

- Range of profiles available, including Stramit's Corrugated, Longspan®, K-Panel® and Monoclad® profiles

- Can be used vertically and horizontally

- Manufactured from high tensile steel for high strength and low weight

- Simple to install

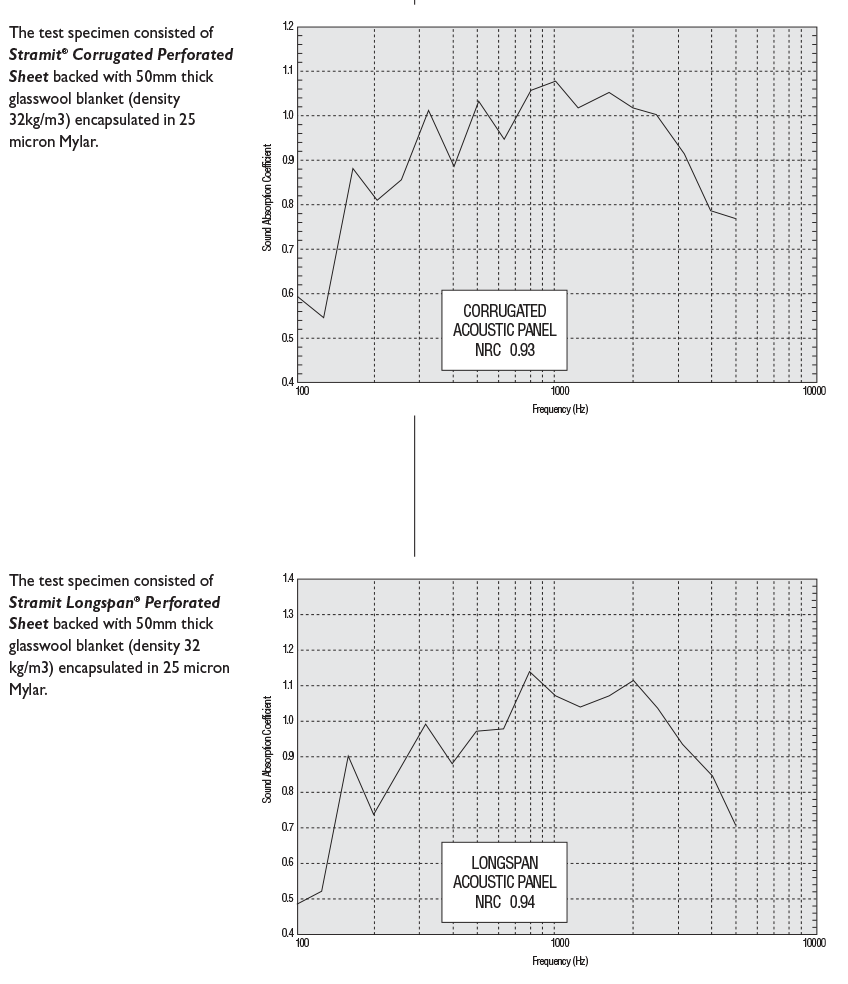

- Exceptional sound reduction performance High sound absorption with NRC's in excess of 0.93 Tested in accordance with ASI 045 for sound absorption

Base Material Thickness (mm), 0.42 Finish, G550 coated steel

Limited colour range is available so please contact your local Stramit office for further information on availability.

Where to Buy

Stramit account holders can buy the Stramit® Acoustic Panel System from their local Stramit office. We do not sell direct to the public but our products are stocked by retail outlets across Australia.

Availability

This product is available Australia-wide. Lead times may vary depending on location.

News and Case Studies

Check out Stramit’s latest news, product releases and updates, and case studies featuring our quality Aussie-made steel products.

General Information

Many internal applications for Stramit Perforated or Acoustic Sheets will be relatively benign. In applications of high humidity or corrosive environments, contact your local Stramit office to discuss the optimum material choice.

All building products need to be checked for compatibility with adjacent materials. These checks need to be for both direct contact between materials, and where water runs from one material to another.

Stramit products should be handled with care at all times to preserve the product capabilities and quality of the finish.

Packs should always be kept dry and stored above ground level while on site. If the products become wet, they should be separated, wiped and placed in the open to promote drying.

The Stramit® Acoustic Panel System is supplied cut to length. When designing or transporting long products ensure the length is within the limit of the local Transport Authority regulations.

Manufacturing tolerance on length of product supplied is +0, -15mm.

All Stramit panels are made from steel that confirms with AS 1397.

Stramit has in-house, purpose built testing equipment used to design, develop and improve products for the Australian market.

Many of our products are tested or witnessed by independent organisations. These include University of Technology, Sydney; Cyclone Testing Station (James Cook University), The University of Sydney; and CSIRO.

Sound absorption tests on Stramit® Acoustic Sheets have been conducted by National Acoustic Laboratories using the reverberation chamber method in accordance with AS 1045.

The ongoing research and development activity ensures we remain at the forefront of innovation, design and consumer information.

Technical Information

The wall cladding shall be 0.42 mm BMT Stramit® Acoustic Panel System in continuous lengths with ribs XXmm high, and a cover of XXXmm. Sheeting material shall be protected steel sheet to AS1397 with a minimum yield stress of 300MPa (Grade G300) and an AM100 zinc-aluminium-magnesium coating with an oven-baked paint film of selected colour, or a plain AM125/AZ150 coating.

The sheeting shall be fixed to the structure in accordance with the manufacturer's instructions. All sheeting shall be fixed in a professional manner, leaving the job clean and with minor blemishes touched up with paint supplied by the manufacturer. All insulation/absorbing materials shall match the Stramit specification contained in the Stramit technical brochure.

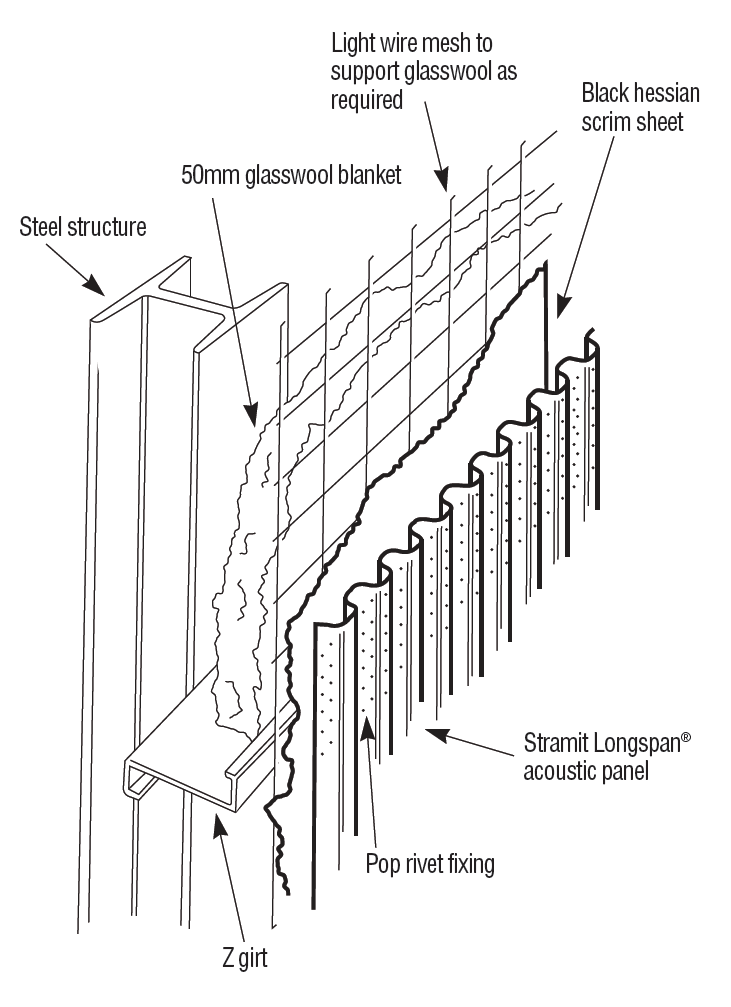

Stramit® Acoustic Panels are installed using typical cladding fixing methods . Designers need to determine the best way of holding the glass wool blankets in place (either against or 75mm away from the back of the panel) to suit the structure or method of construction applied.

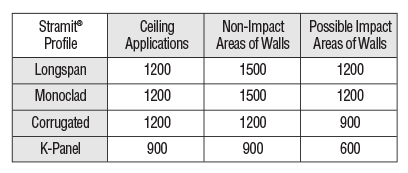

For wall areas likely to be subject to human impact, sheeting spans should be reduced. Impact loads will vary considerably and these are not prescribed in Australian Standards.

A maximum span of 900mm is suggested for such areas, but this should be adjusted dependent upon the exposure and importance of the application.

Stramit® Acoustic Panels are cold roll formed cladding sheets produced from pre-perforated COLORBOND® steel materials. Steel is G550 base material (G550 Mpa minimum yield stress with a ZINCALUME® steel (AM100 coating, in accordance with AS1397), plus an off-white COLORBOND® finish coat.

Standard steel thickness is 0.42mm BMT (base material thickness). Other materials, such as unpainted ZINCALUME® or galvanised steel, stainless steel, aluminium and copper can be roll formed subject to enquiry.

Stramit standard perforations cover approximately 11% of the cladding surface. Holes are 2.4mm in diameter and are pitched symmetrically across the sheet.

This layout gives the best balance between appearance, ease of installation cladding performance and noise reduction.

Contact our technical services consultants if you require a different hole pattern.

The following graphs give the performance levels obtained with the absorption material (the glasswool blanket) immediately behind the acoustic panel.

Improved figures are possible if the panel and glasswool blanket are separated with a 75mm air gap.

The tests described within these product pages used:

- Stramit Corrugated or Stramit Longspan perforated sheet

- Insulation Solutions Sonobatt type I glass wool insulation with a density of 32kg/m3

- With or without a 75mm air gap between the perforated sheet and the insulation

Any variation to these specifications could result in a change in acoustic performance. Generally a NRC over 0.6 will give a noticeable increase in acoustic comfort, while NRC's over 0.8 are excellent

As a guide the following changes will affect the NRC values given in the graphs

- Use of 75mm air gaps increase NRC by 0.02

- Use of 75mm Sonobatt will increase NRC by 0.1

- Stramit Monoclad or Stramit K-Panel Perforated Sheets will reduce NRC by 0.1

- Use of 50mm Sonomatt (14kg/m3) reduces NRC by 0.2.

These variations are approximate only and have been determined from previous Insulation Solutions test results.

Acoustic panels may be subjected to loads from impact or limited by acceptable deflection. Maximum recommended spans in millimetres for each profile are shown in the table below.

For most expected applications, the panels will not be subject to wind or foot traffic loading. However if either should be applicable, refer to the profile-specific Product Technical Manual for these capacities.

In addition to the glass wool acoustic properties, this system also provides reasonable thermal performance. 50mm Sonobatt insulation provides a thermal resistance rating of approximately R = 1.5.

Designers should be aware of this and if condensation is anticipated, adequate ventilation and/or vapour barriers should be provided to protect the acoustic panels.

Installation Information

Stramit's cladding can be easily cut, where required, using a power saw with a steel cutting blade or a power nibbler and, for localised cutting, tin snips. Avoid the use of abrasive discs as these can cause burred edges and coating damage. Please dispose of any off-cuts carefully.

Consideration should be given to handling and installation issues as part of site induction safety procedures. Specific consideration should be given to pack handling, avoidance of cuts, trips, slips and falls, long section handling, particularly in windy conditions, section cutting procedures and surface temperature on sunny days.

Wear safety glasses with side shields when cutting or trimming product. Cut resistant or leather gloves should be worn when handling product. Foot protection should be warn when handling and transporting product.

Stramit recommends installers follow the installation code for metal roofing and wall cladding as outlined in the Standard Australia Handbook – HB39.

Should it be necessary to wash Stramit Perforated or Acoustic Sheets, use the following procedure:

- Wash the surface with a mild solution of pure soap or non-abrasive, non-toxic, kitchen detergent in warm water using a sponge, soft cloth or a soft bristle nylon brush.

- Thoroughly rinse with clean water immediately after use.

- Never use abrasive or solvent type cleaners, such as turps, petrol, thinners or kerosene, on COLORBOND® steel.