Share with

- Range of thicknesses offers design efficiency

- Simple screw fasteners and screw ridges make it quick and easy to install

- Easy to handle and store

Stramit® Top Hats are manufactured from high-tensile (G550/G500) steel with either AZ150 zinc-aluminium alloy or Z350 galvanised coating conforming to AS1397.

Contact your local Stramit office to discuss other coatings, grades and materials options.

Where to Buy

Stramit account holders can buy Stramit® Top Hats from their local Stramit office. We do not sell direct to the public but our products are stocked by retail outlets across Australia.

Availability

This product is available Australia-wide. Lead times may vary depending on location.

News and Case Studies

Check out Stramit’s latest news, product releases and updates, and case studies featuring our quality Aussie-made steel products.

General Information

Stramit® Top Hats will give excellent durability in most applications. In exposed conditions, unwashed areas subject to salt-laden air or other corrosive matter may need additional protection. Stramit® Top Hats are not recommended for use in enclosed areas within 450mm of moist soil.

Stramit recommends that all designs conform to relevant Australian Standards such as AS1170 series (Loading Codes), AS4600 (Cold-formed steel structures) and AS3623 (Domestic metal framing).

All building products need to be checked for compatibility with adjacent materials, whether they be part of the current project or pre-existing or planned building elements.

Avoid placing on or in conjunction with components made from copper, lead, green or treated timber, stainless steel and mortar or concrete.

Contact your local Stramit office for more detailed information.

Stramit structural products should be handled with care.

Packs should always be kept dry and stored above ground level while on site. If the sections have become wet, they should be separated, wiped and placed in the open to promote drying.

Stramit® Top Hats are available in stock lengths or cut to length (minimum and maximum lengths may apply).

Contact your local Stramit Office or refer to the Stramit Product and Service Guide for your area for further detail.

Stramit's structural products are protected in Australia by registered designs.

Contact our technical services consultants if you require further information or advice for your local conditions and practices.

Stramit has in-house, purpose built testing equipment used to design, develop and improve products for the Australian market.

Many of our products are tested or witnessed by independent organisations. These include University of Technology, Sydney; Cyclone Testing Station (James Cook University), The University of Sydney; and CSIRO.

The ongoing research and development activity ensure we remain at the forefront of innovation, design and consumer information.

Technical Information

All top hats shall be Stramit sections or approved equivalent supported by submission of section properties and capacity calculations/data in accordance with AS4600,AS3623 and AS1562.

All sections shall be produced from high-tensile G500/G550 steel with a galvanised/zinc-aluminium alloy coating conforming to AS1397.

All sections must be installed in accordance with the manufacturer's recommendations with particular reference to the number, size, grade and positioning of fasteners.

Limit-state design capacity tables for Stramit Top Hats for use in non-cyclonic areas can be found in the Stramit Top Hat Sections Product Technical Manual.

Contact your local Stramit office for information on use of the products in cyclonic areas.

Information on using top hats in cyclonic region can be found in our Top Hat Cyclonic Design Supplement Customer Update.

Contact your local Stramit office for further information on use of Stramit Top Hats in cyclonic regions.

Information on the use of the Stramit Cyclonic Roof Batten in the Darwin area can be found in the deemed to comply sheets in the Darwin Area Manual. These sheets can also be obtained from your local Stramit office.

Each application must conform to the specific details outlined in the Design Data Sheets.

End fastenings of top hats are recommended to be at least 25mm from the section end irrespective of whether this occurs at the structure end or at an internal support.

Remember to allow for this additional material over and above the span length/s and laps when specifying, ordering or cutting sections.

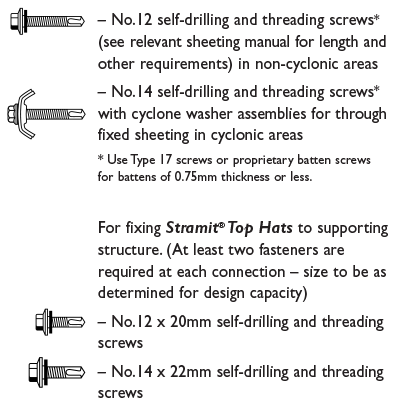

The following fasteners are recommended for fixing sheeting to Stramit Top Hats.

Stramit can also supply cold formed steel sections that can be used for stud, plant and nogging frames. These conventional sections are easily assembled using conventional techniques.

Lapped Stramit® Top Hat configurations require a minimum 10% lap length (i.e. 5% at each end). Section properties within the lap have been assumed to be twice that of a single section rather than the properties of a double thickness section.

End fastenings of top hats are recommended to be at least 25 mm from the section end irrespective of whether this occurs at the structure end or at an internal support. The absolute minimum required by AS4600 is 1.5 df (where df is the nominal screw diameter). Remember to allow for this additional material over and above the span length/s when specifying, ordering or cutting sections.

Stramit® Top Hats TH96 and TH64 have one end partially crimped to facilitate lapping. Top hat overlaps (or non-structural laps) are recommended to be 100 mm in length. In these cases structural continuity must not be assumed.

Double Spans are simply supported and attached at each end and in the middle (unlapped) or have a structural (10%) lap at that central support (lapped).

Triple Spans are also simply supported and attached at each end and at two equally spaced intermediate supports (unlapped) or have a structural (10%) lap at those intermediate support (lapped).

The Stramit® Top Hats & Battens Capacity Tables Product Technical Manual or 120mm Top Hat Technical Supplement has further information.

All loadings used in deriving the design data are assumed to either act uniformly along the top central flange of the sections or, for connections to support members, evenly between each of the lower flanges (feet).

Foot traffic loadings, where used, are based on AS1562.

Stramit® Top Hats are manufactured from high-tensile (G550/G500) steel with either AZ150 zinc-aluminium alloy or Z350 galvanised coating in full conformance with AS1397.

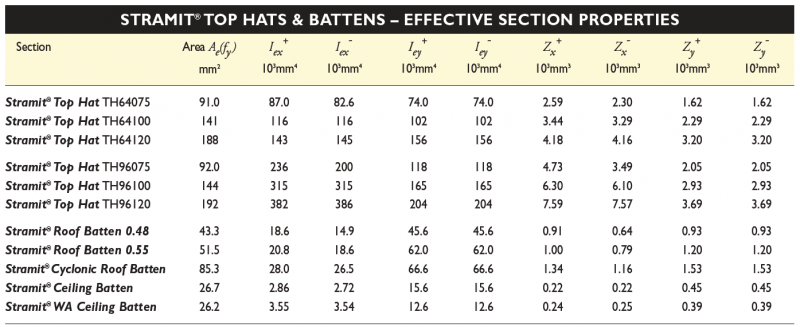

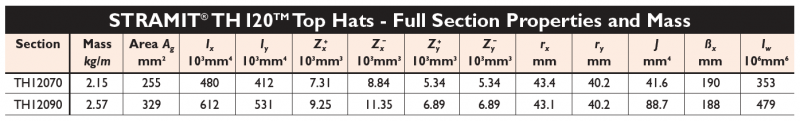

Section properties are available for all Stramit® Top Hats and this data is contained within the relevant Top Hats Capacity Tables Product Technical Manual.

Stramit® Top Hats are available in a range of sizes, selected to match the dimensions of adjacent structural members. Additionally all Stramit® Top Hats are available in various thicknesses to allow designers flexibility between performance and economy. Size and mass details are below:

Member, fastener or roof sheeting capacity influences top hat spacing. It is often economical to reduce top hat spacing at the building edge and ends to account for the higher wind pressures encountered on these parts of the building. Additional runs may be required adjacent to roof penetrations or in areas of additional loading.

Installation Information

Should cutting be required, use a power saw with a steel cutting blade or a power nibbler. Avoid the use of abrasive discs as these can cause burred edges. Please dispose of any off-cuts carefully and thoughtfully.

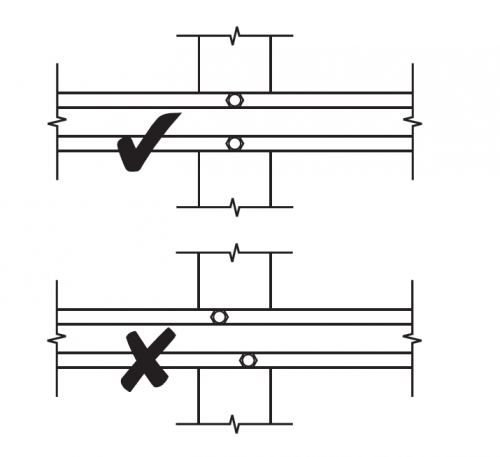

Always use the correct size and quantity of fasteners as specified by the design engineer. Pairs of screws at connections must be directly in line (parallel with the supporting member).

Structural laps for Stramit® Top Hats require a minimum 10% lap length (i.e. 5% at each end). End fastenings of top hats should be at least 25mm from the section end irrespective of whether this occurs at the structure end or at an internal support. Remember to allow for this additional material over and above the span length/s when specifying, ordering or cutting sections.

Top hat overlaps (or non-structural laps) are recommended to be 100 mm in length. In these cases structural continuity must not be assumed. When connecting overlapping top hats place foot onto upper section to nest sections prior to and during fixing. Laps must be fastened through both webs near both ends of the lap.

Consideration should be given to handling and installation issues as part of site induction safety procedures. Specific consideration should be given to pack handling, and avoidance of cuts, trips, slips and falls, long section handling, particularly in windy conditions, and surface temperature on sunny days.

Wear safety glasses with side shields when cutting or trimming product. Cut resistant or leather gloves should be worn when handling product. Foot protection should be warn when handling and transporting product.

Stramit recommends that good trade practice be followed when using these products, as outlined in AISC/Australian Standards HB62 part 1 and HB39.

Stramit® Top Hat sections have been designed to withstand foot traffic load during installation and service. The use of appropriate cradles or cherry pickers is recommended. As a minimum, never walk on purlins without safety mesh in place. Do not walk on girts.

Stramit does not recommend the welding of top hats. The heat produced in welding will affect the material properties of the high-tensile cold-formed steel used by Stramit in all its sections.

In many instances considerable stress concentrations are likely to arise, even with good quality welding. In addition, welding will locally remove the galvanized coating leading to a potential reduction in durability.