Australian Made Purlins and Girts from Stramit

30 August 2023

Stramit’s Australian-made purlins and girts offer a range of solutions for industrial, commercial and rural buildings.

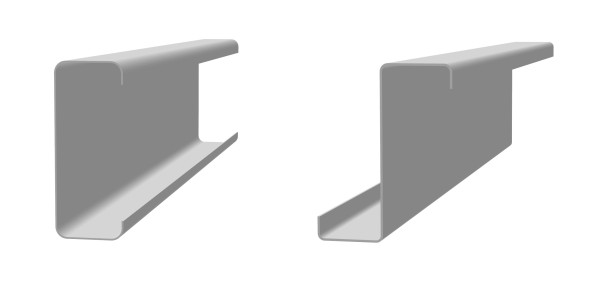

Stramit's range of Purlins and Girts in C & Z profiles will match existing or new project specification, and come in a range of traditional sizes as well as coating options to suit corrosivity requirements.

While most commonly attached to fabricated steel frames, C and Z sections can also be used as the structural frame in small and medium sized buildings.

All Stramit Purlins and Girts are proudly Australian Made, roll formed at sites across the country to support building projects in every community.

What’s the difference between C and Z Purlins?

C sections are ideally suited to single, non-continuous span construction. C purlins are often favoured for their stability in single spans and are also adaptable to doubly symmetric “I” and “box” configurations.

Z sections can be used for single spans and in unlapped and lapped continuous span construction. Continuously lapped Z purlins generally provide the greatest economy for medium and large buildings.

What size options are available?

Available sizes:

- 150mm

- 200mm

- 250mm

- 300mm

- 350mm

What materials are Stramit® Purlins and Girts available in?

Stramit C&Z Purlins and Girts are manufactured from hi-tensile GALVASPAN® steel, with a minimum Z350 galvanised coating (350g/m2) or ZAM® coated steel conforming to AS1397.

High tensile steel offers high strength, with low weight.

Chat to your Stramit Account Manager, or reach out to your local office, to discuss other coatings, grades and materials options.

What complementary products or accessories are available with Stramit® Purlins and Girts?

Stramit has also designed a range of bridging assemblies to offer a complete bridging system. This system offers a range of components which are both speedy to install and versatile in design solutions.

For more information about bridging please visit our product page.

Purlin accessories like brackets and bolts are also available, as well as a downturn lip including lappable Zs for projects requiring this feature.

Stramit Exacta® C and Z Purlins

Stramit has performance optimised the most commonly used spans, resulting in Exacta® C and Z Purlins, which can lead to capacity improvements up to 18%.

How? It’s thanks to Stramit’s state-of-the-art-manufacturing equipment and high standards of quality control.

Exacta® Purlins also have complementary moment capacity design software, for alternative span configurations. This software helps you take control of purlin design and optimisation, and to make economical decisions with purlin solutions. Stramit’s EX-facta™ software can be downloaded here.

Like the standard range of purlins, Exacta® purlins are made of high-tensile steel.

Learn more about Stramit® Purlins and Girts, or download technical resources and materials, here.

More stories you may be interested in

31 July 2023

5 Ways to Use Stramit’s SharpLine® Architectural Cladding

Stramit’s SharpLine® architectural cladding is known for its on-trend, modern aesthetic and showcases a select range of premium co…

19 August 2024

The Future of Logistics: Light Horse Hub’s Multifunctional Design Powered by Stramit Steel

The Light Horse Logistics Hub in Eastern Creek, NSW, stands as a beacon of sustainable and innovative design on Darug land.

This …